Manufacturing Challenges and Solutions

IDDS, in particular, has enabled the phenomenal growth of drug delivery systems during the past decade. It allows for a controlled and directed mode of administration, thereby maximizing the therapeutic effect with minimum adverse side effects. However, manufacturing these devices poses special challenges that must be resolved before this therapeutic device is fully utilized.

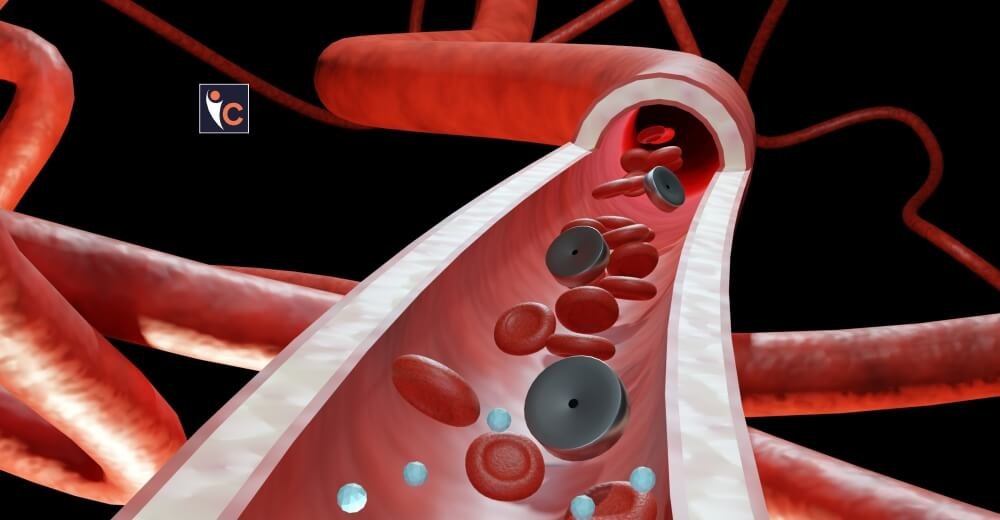

Understanding Implantable Drug Delivery Systems

Implantable Drug Delivery Systems are designed to release therapeutic agents over extended periods, ranging from weeks to years. They function as internal repositories that provide precise doses directly at the site of action or into systemic circulation. This method contrasts sharply with traditional oral medications, which often suffer from erratic absorption and limited bioavailability.

Key Benefits of IDDS:

Targeted Action: Drugs can be delivered directly to the site of interest, reducing systemic exposure.

Improved Patient Compliance: Reduced frequency of administration leads to better adherence to treatment regimens.

Sustained Release: These systems can maintain therapeutic drug levels over time, avoiding peaks and troughs associated with conventional dosing methods.

Manufacturing Challenges

Despite their advantages, the development and manufacture of IDDS face several challenges:

Material Selection:

In case of implantable devices, one has to select biomaterials that are biocompatible and biodegradable. The major challenge is to provide drug release with safety and biocompatibility with human tissues. Usual candidates are PLGA and PDMS, but they are under challenge due to variable degradation rates and unsatisfactory mechanical properties.

The design of IDDS often involves intricate geometries that must facilitate controlled drug release. This complexity can complicate the manufacturing process, requiring advanced techniques such as 3D printing or microfabrication methods. Ensuring uniformity in drug distribution within the device is critical for consistent release profiles.

Regulatory Hurdles:

The regulatory environment regarding medical devices is very strict: it takes a lot of testing and approval for manufacturers to prove the safety and efficacy of a device before its market release. In fact, these can extend timelines and raise development costs by a great amount.

Scalability:

Transitioning from laboratory-scale production to large-scale manufacturing poses significant challenges. Maintaining quality control while scaling up production is essential to ensure that each device meets the required specifications.

Solutions to Manufacturing Challenges

Addressing these challenges requires innovative approaches:

Advanced Material Development:

Research into new biomaterials that offer improved biocompatibility and controlled degradation rates is ongoing. For instance, incorporating nanoparticles into polymer matrices can enhance drug loading capacity and modify release kinetics.

Utilizing 3D Printing Technologies:

3D printing allows for the precise fabrication of complex structures that can be tailored to specific therapeutic needs. This technology can enable rapid prototyping and customization of IDDS, facilitating better patient-specific solutions.

Implementing Smart Manufacturing Techniques:

The integration of smart technologies such as IoT (Internet of Things) can enhance monitoring during the manufacturing process. Real-time data collection can help identify issues early on, ensuring consistency and quality across batches.

Collaborative Regulatory Strategies:

Engaging with regulatory bodies early in the development process can streamline approvals. Collaborative efforts between manufacturers and regulators can lead to clearer guidelines, reducing uncertainty during product development.

Future Directions

IDDS, therefore, undeniably has a great future ahead, since research is ongoing in developing their functionalities through smart technologies and personalized medicine approaches. An example could be closed-loop systems, in which the potential for real-time response against physiological alterations may bring about a sea change in chronic condition management because drug delivery rates can be automatically altered in accordance with patient requirements.

Besides, new nanotechnology enables new sophisticated ways of drug delivery that will reach cells and tissues more precisely than ever before. As such technologies mature, they hold a promise of not just improved patient outcomes, but also minimization of overall healthcare costs due to reduced hospitalization rates caused by medication non-compliance or medication adverse events.

Conclusion

In the field of implantable drug delivery systems, much has been accomplished in developing novel therapeutic delivery methodologies that afford some advantages compared to more ‘classical’ routes of administration. However, manufacturing issues to be resolved include material selection, design complexity, regulatory compliance, and scalability if clinical applications are to become common. Advanced materials science coupled with innovative manufacturing methods, such as 3D printing and collaborative regulatory strategies, may provide solutions for these challenges. Research in this area is evolving daily, and IDDS will most likely continue to play an even greater role in personalized medicine and management of chronic diseases, eventually leading to improvements in the care of, and health outcomes for, patients worldwide.